What Amperage Is 10 Gauge Wire Rated For? A Comprehensive Guide

Electrical wiring is a critical component of any electrical system, and understanding the capacity of different wire gauges is essential for ensuring safety and efficiency. One of the most commonly used wire gauges in various applications is the 10 gauge wire. Knowing what amperage a 10 gauge wire is rated for is crucial for anyone working with electrical systems, whether you're a professional electrician or a DIY enthusiast.

Choosing the right wire gauge for your project involves more than just selecting the thickest wire available. It requires an understanding of the relationship between wire gauge, amperage, and voltage drop, as well as the specific application for which the wire will be used. In this article, we will explore the amperage rating of 10 gauge wire, its applications, and how to select the appropriate wire for your needs.

By the end of this guide, you will have a thorough understanding of what amperage a 10 gauge wire can handle, along with practical tips to ensure your electrical installations are safe and compliant with industry standards.

Read also:Leslie Bogart The Remarkable Journey Of A Hollywood Icon

Table of Contents

- Introduction to Wire Gauges

- What Amperage is 10 Gauge Wire Rated For?

- Understanding Wire Gauge Ratings

- Applications of 10 Gauge Wire

- Voltage Drop Considerations

- Proper Installation Techniques

- Safety Precautions When Using 10 Gauge Wire

- Comparison with Other Wire Gauges

- Factors Affecting Wire Amperage Rating

- Conclusion and Final Thoughts

Introduction to Wire Gauges

Wire gauges are standardized systems used to specify the diameter of electrical wires. The American Wire Gauge (AWG) system is the most commonly used standard in the United States and many other countries. Each gauge number corresponds to a specific wire diameter, with lower numbers indicating thicker wires and higher numbers indicating thinner wires.

Understanding wire gauges is essential because the diameter of a wire directly affects its ability to carry electrical current. Thicker wires can handle higher amperages without overheating, while thinner wires are suitable for lower amperage applications.

For instance, a 10 gauge wire is commonly used in residential wiring for applications such as branch circuits, lighting, and small appliances. Its ability to carry a significant amount of current makes it a versatile choice for many electrical installations.

What Amperage is 10 Gauge Wire Rated For?

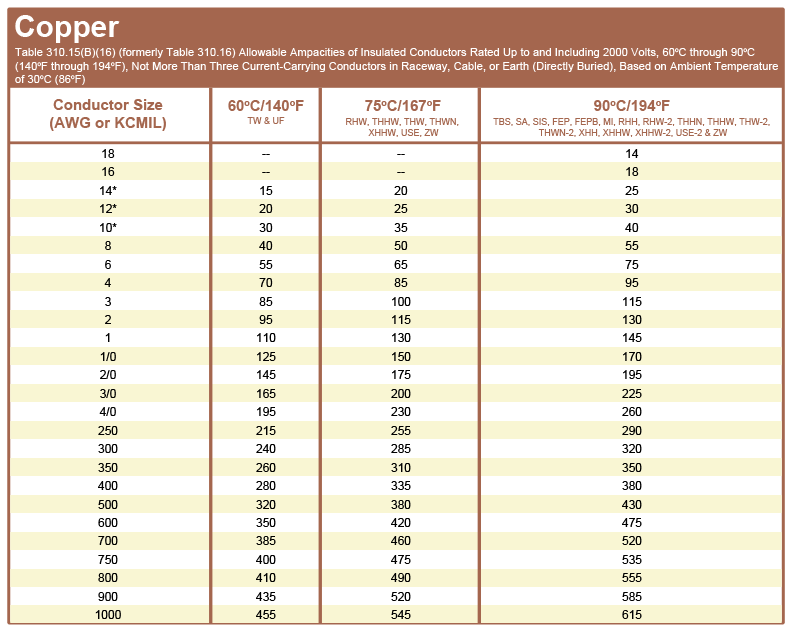

A 10 gauge wire is typically rated for up to 30 amps at a temperature of 75°C (167°F). This rating is based on the wire's ability to safely carry electrical current without overheating or causing damage to the insulation. However, the actual amperage capacity can vary depending on factors such as the length of the wire, the environment in which it is installed, and the type of insulation used.

For example, if the wire is installed in a high-temperature environment or is part of a long circuit, the amperage rating may need to be reduced to ensure safe operation. In such cases, it is important to consult the National Electrical Code (NEC) or other relevant standards to determine the appropriate derating factors.

Amperage Ratings for Different Insulation Types

- 75°C (167°F) insulation: 30 amps

- 90°C (194°F) insulation: 35 amps

- 60°C (140°F) insulation: 25 amps

It is crucial to match the wire's insulation type with the expected operating conditions to ensure safe and reliable performance.

Read also:What Does Shane Gillis Do Exploring The Multifaceted Career Of A Rising Star

Understanding Wire Gauge Ratings

Wire gauge ratings are determined based on several factors, including the wire's diameter, material, and insulation properties. The AWG system provides a standardized way to specify wire sizes, making it easier to select the appropriate wire for a given application.

In general, larger gauge numbers correspond to thinner wires, while smaller gauge numbers indicate thicker wires. For example, a 12 gauge wire is thinner than a 10 gauge wire, and a 6 gauge wire is thicker than both.

The amperage rating of a wire is inversely proportional to its gauge number. This means that thicker wires (lower gauge numbers) can carry more current than thinner wires (higher gauge numbers). For instance, a 10 gauge wire can handle more amperage than a 12 gauge wire but less than a 6 gauge wire.

Common Wire Gauge Ratings

- 14 gauge: 15 amps

- 12 gauge: 20 amps

- 10 gauge: 30 amps

- 8 gauge: 40 amps

These ratings are based on standard conditions and may vary depending on specific application requirements.

Applications of 10 Gauge Wire

Due to its ability to carry a significant amount of current, 10 gauge wire is widely used in various electrical applications. Some common uses include:

- Branch circuits in residential and commercial buildings

- Power supply for small appliances such as air conditioners and water heaters

- Outdoor lighting and landscape lighting systems

- Extension cords for heavy-duty tools and equipment

When selecting wire for a specific application, it is important to consider factors such as the length of the circuit, the expected load, and the operating environment. Proper wire selection ensures safe and efficient operation of electrical systems.

Residential Wiring Applications

In residential wiring, 10 gauge wire is often used for circuits that require higher amperage, such as those powering electric water heaters, air conditioning units, and electric ranges. Its ability to handle up to 30 amps makes it suitable for these applications, where lower gauge wires may not be sufficient.

Voltage Drop Considerations

Voltage drop is an important consideration when designing electrical circuits. It refers to the reduction in voltage that occurs as current flows through a wire. Excessive voltage drop can lead to poor performance of electrical devices and increased energy consumption.

The amount of voltage drop depends on several factors, including the length of the wire, the current flowing through it, and the wire's resistance. For a 10 gauge wire, the voltage drop is generally acceptable for circuits up to 50 feet in length when carrying up to 30 amps. However, for longer circuits or higher current loads, larger gauge wires may be necessary to minimize voltage drop.

Calculating Voltage Drop

To calculate voltage drop, you can use the following formula:

Voltage Drop (%) = (2 × Length × Current × Resistance) ÷ (Voltage × 100)

Where:

- Length is the one-way length of the wire in feet

- Current is the load current in amps

- Resistance is the resistance of the wire in ohms per 1,000 feet

- Voltage is the circuit voltage in volts

Using this formula, you can determine whether the voltage drop in your circuit is within acceptable limits.

Proper Installation Techniques

Proper installation of electrical wiring is critical for ensuring safety and reliability. When working with 10 gauge wire, it is important to follow best practices to avoid potential hazards.

Some key installation tips include:

- Using wire strippers to remove insulation without damaging the wire

- Tightening connections securely to prevent loose connections

- Labeling wires clearly to facilitate future maintenance

- Ensuring all wiring is properly grounded

Following these guidelines helps ensure that your electrical system operates safely and efficiently.

Best Practices for Wiring Connections

When making wiring connections, it is important to use the appropriate tools and techniques. For example, using wire nuts or crimp connectors can help ensure secure and reliable connections. Additionally, applying anti-oxidant grease to aluminum wires can prevent corrosion and improve conductivity.

Safety Precautions When Using 10 Gauge Wire

Safety should always be a top priority when working with electrical systems. When using 10 gauge wire, it is important to follow proper safety precautions to avoid accidents and injuries.

Some key safety tips include:

- Turning off power to the circuit before working on it

- Using personal protective equipment (PPE) such as gloves and safety glasses

- Avoiding overloading circuits beyond their rated capacity

- Regularly inspecting wiring for signs of damage or wear

By following these safety precautions, you can help ensure a safe working environment and prevent potential hazards.

Common Electrical Hazards

Some common electrical hazards to be aware of include:

- Overloaded circuits

- Damaged or frayed wires

- Improper grounding

- Exposure to moisture or water

Addressing these hazards promptly can help prevent accidents and ensure the longevity of your electrical system.

Comparison with Other Wire Gauges

Understanding how 10 gauge wire compares to other wire gauges can help you make informed decisions about wire selection for your projects. Here is a comparison of some common wire gauges:

- 14 gauge: Rated for 15 amps, suitable for lighting and small outlets

- 12 gauge: Rated for 20 amps, suitable for general-purpose circuits

- 10 gauge: Rated for 30 amps, suitable for heavy-duty circuits

- 8 gauge: Rated for 40 amps, suitable for high-power appliances

Each wire gauge has its own advantages and limitations, so it is important to select the appropriate wire for your specific application.

Choosing the Right Wire Gauge

When selecting a wire gauge, consider factors such as the expected load, circuit length, and environmental conditions. Consulting the NEC or other relevant standards can help ensure compliance with safety regulations and industry best practices.

Factors Affecting Wire Amperage Rating

Several factors can affect the amperage rating of a wire, including:

- Wire diameter: Thicker wires can carry more current

- Insulation type: Different insulation materials have different temperature ratings

- Operating environment: High temperatures or moisture can reduce a wire's amperage capacity

- Circuit length: Longer circuits may require larger gauge wires to minimize voltage drop

Considering these factors when selecting wire for your project can help ensure safe and efficient operation.

Derating Factors

Derating factors are adjustments made to a wire's amperage rating to account for specific operating conditions. For example, if a wire is installed in a high-temperature environment, its amperage rating may need to be reduced to ensure safe operation. Consult the NEC or other relevant standards for specific derating guidelines.

Conclusion and Final Thoughts

In conclusion, understanding what amperage a 10 gauge wire is rated for is essential for anyone working with electrical systems. A 10 gauge wire is typically rated for up to 30 amps, making it suitable for a wide range of applications, including branch circuits, small appliances, and outdoor lighting. Proper selection and installation of wire are critical for ensuring safety and efficiency in electrical systems.

We encourage you to leave a comment below if you have any questions or additional insights about wire gauges and amperage ratings. Sharing this article with others who may find it useful is also greatly appreciated. For more information on electrical wiring and related topics, be sure to explore our other articles on the site.